Next Generation of Waste Treatment Technology.

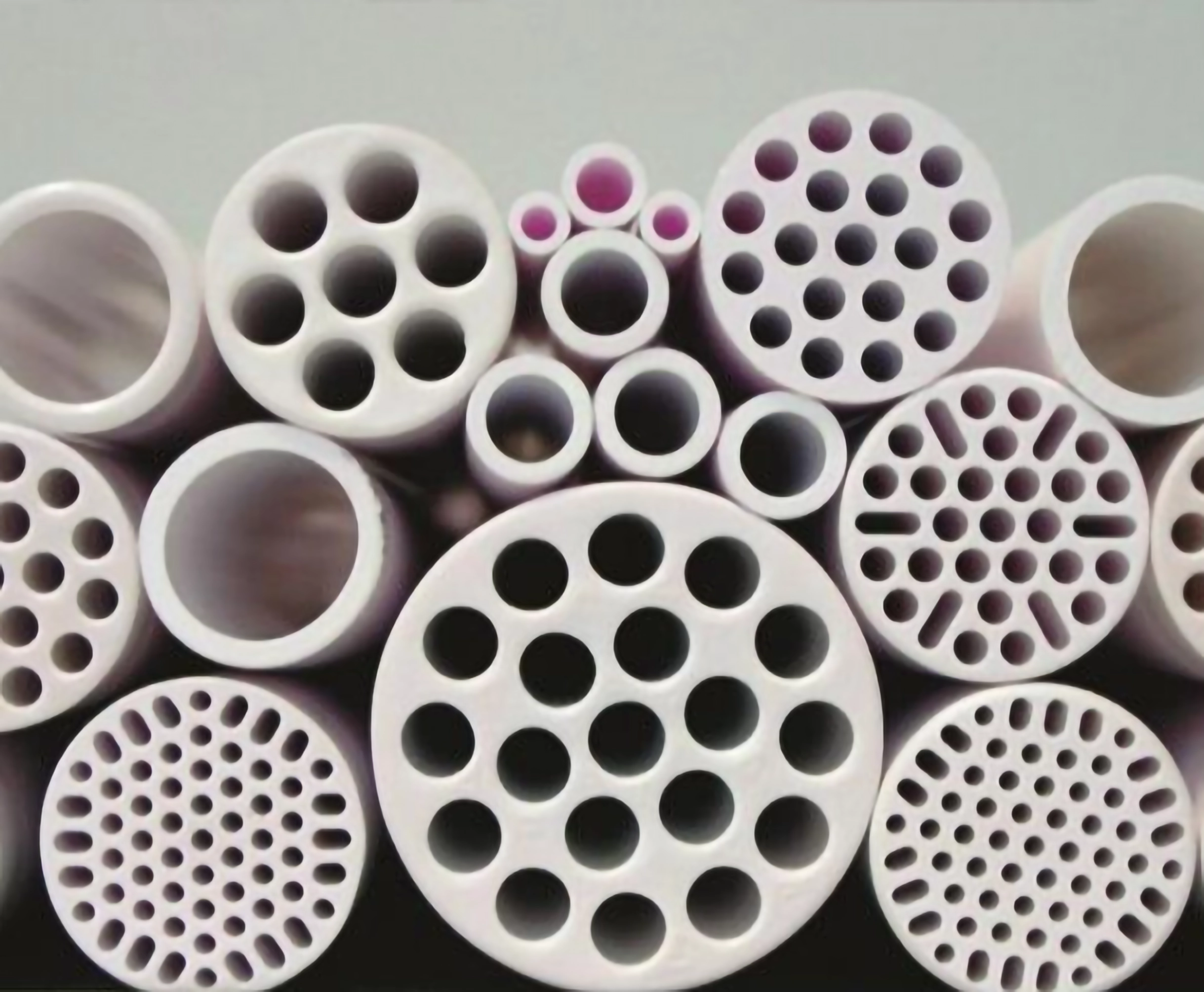

Ceramic Membrane Bioreactors (CMBRs) represent the next generation of wastewater treatment technology, combining the robustness of ceramic membranes with the efficiency of biological treatment processes. ECOCEPT Bio Renewables leverages CMBRs to deliver unparalleled performance in treating industrial effluents, ensuring compliance with environmental regulations while promoting sustainability.

We are excited for our work and how it positively impacts clients.